Japan's Naval Railgun Test: What Its Success Means vs. the US Navy's "Cracked Barrels" Failure

The railgun was supposed to be the U.S. Navy’s silver bullet. A weapon that bypassed chemical propellants entirely, using raw electromagnetic force to launch a projectile at speeds exceeding Mach 6. The kinetic energy alone—equivalent to a one-ton vehicle hitting a wall at 160 miles per hour—would obliterate targets without the need for explosives. The Office of Naval Research poured years and, by some estimates, over half a billion dollars into the program.

And then, it vanished.

The official post-mortem was a tidy list of insurmountable engineering hurdles. The power requirements were astronomical, demanding 20-30 megajoules per shot, a load only the specialized Zumwalt-class destroyers could even theoretically handle. The rate of fire was too slow. But the fatal diagnosis, the one that truly shuttered the project, was a problem summed up by the headline ‘Cracked Barrels’: The U.S. Navy’s Big Railgun Failure Explained in Just 2 Sad Words. The immense heat and electromagnetic stress were reportedly destroying the gun’s barrel in fewer than 30 shots. It was an operational dead end.

So, the Navy salvaged what it could. The program’s real triumph, the Hypervelocity Projectile (HVP), was decoupled from its futuristic launcher and adapted for conventional 5-inch naval guns and Army howitzers. It was a pragmatic pivot, but it felt like a quiet admission of defeat. The dream of the electromagnetic cannon was shelved.

Except, it seems someone forgot to tell Japan. While the U.S. was writing its obituary for the railgun, Japan’s Acquisition, Technology & Logistics Agency (ATLA) was systematically solving the very problems the Pentagon had deemed intractable. The discrepancy in the data is jarring.

A Tale of Two Data Sets

Let’s be precise about the American failure metric. The core issue wasn't the physics; it was the materials science. The barrel, the rails guiding the projectile, simply couldn't withstand the repeated violence of a 3-to-5-million-amp discharge. Longevity is a non-negotiable variable in weapons systems. A gun that destroys itself after a few dozen rounds isn't an asset; it's a logistical nightmare. I've looked at countless R&D write-offs in the corporate world, and this pattern is familiar: a promising technology gets 90% of the way there, but the final 10%—the part involving durability and cost-effective operation—proves to be an impassable chasm. The U.S. Navy hit that chasm and decided to stop digging.

This is what makes the data coming out of Japan so compelling. ATLA, which began its research in 2016, set a clear target: a barrel life of 120 rounds. That's a 4x improvement, at a minimum, over the reported U.S. performance. And according to their public statements, they achieved it. In tests running through 2022, they confirmed "no significant damage occurred to the barrel rail even after 120 rounds were fired."

How? The answer appears to be a focused effort on metallurgy (a detail conspicuously absent from most U.S. post-mortems). While early prototypes used copper for the rails, ATLA moved to a different, undisclosed blend of metals and materials specifically engineered to handle the thermal and physical stresses. This isn’t a revolutionary leap in physics; it’s a grinding, incremental victory in materials engineering. It’s the kind of unglamorous work that doesn't generate exciting headlines but makes the difference between a lab curiosity and a viable weapon.

The Japanese progress didn't stop there. In October 2023, they conducted the world's first ship-board firing of a railgun. By mid-2025, they had mounted a turreted prototype on the test ship JS Asuka and successfully fired it at a target vessel, a milestone reported when the Japanese Warship Fires Railgun At Target Vessel For The First Time. They are now tackling the "total system" problem: developing continuous firing capabilities, creating a dedicated fire control system, and ensuring projectile stability at hypersonic speeds. Their stated velocity is around Mach 6.5—or more precisely, 2,230 meters per second. These are all milestones the U.S. program discussed but never physically reached. Standing on the deck of the Asuka, feeling the low hum of the capacitors charging before the silent, violent launch, must have felt like a profound validation.

The Power Problem and the Path Forward

Of course, the other major hurdle cited by the U.S. Navy—power—remains a significant challenge. Firing a railgun requires a massive, instantaneous burst of energy, which in turn requires a robust generation and storage system. Japan acknowledges this, and miniaturizing the power supply for installation on space-constrained warships is a central goal of their current research phase, which runs to 2026.

But here again, the narrative diverges. The American perspective framed this as a binary problem: either you have a Zumwalt-class ship with its unique Integrated Propulsion System, or you don't. Japan, along with European partners in France and Germany, appears to be treating it as a solvable engineering challenge of scaling and efficiency. Is it possible that the U.S. Navy, facing budget headwinds and a desire for near-term results, simply lacked the institutional patience to see the problem through? Could the focus have been too much on raw power output and not enough on the foundational materials that would make that power usable?

The quiet cooperation between Japan's ATLA and the French-German Research Institute of Saint-Louis (ISL) is another data point worth watching. The exchange of engineers suggests a collaborative, problem-solving approach to a technology the U.S. effectively declared a dead end.

The result is a fascinating strategic paradox. The United States, the originator of the modern naval railgun program, is now leveraging its projectile in legacy systems. Meanwhile, its closest ally in the Pacific is on the verge of fielding the complete weapon system, potentially creating a significant new capability for anti-air and anti-surface warfare. Japan envisions using it to intercept hypersonic missiles and out-range coastal defenses—exactly the missions the Pentagon is currently struggling to counter.

A Discrepancy in Materials, Not Ambition

My analysis of the available data suggests the American narrative that the railgun is "impossible tech" is flawed. It's a conclusion drawn from a specific set of circumstances: a particular approach to materials science, a rigid power requirement tied to a specific ship class, and a budget environment that prioritized near-term, adaptable solutions like the HVP. Japan's success doesn't invalidate the challenges the U.S. faced. It simply proves they were engineering problems, not laws of physics. They were solvable with a different approach and, crucially, sustained investment in the less glamorous field of metallurgy. The story of the railgun isn't one of American failure and Japanese success. It's a case study in how a 400% improvement in a single, critical variable—barrel life—can change the entire strategic calculation.

-

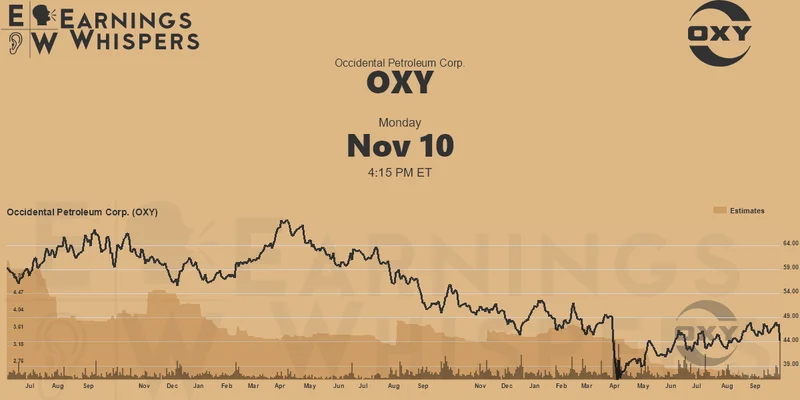

Warren Buffett's OXY Stock Play: The Latest Drama, Buffett's Angle, and Why You Shouldn't Believe the Hype

Solet'sgetthisstraight.Occide...

-

The Great Up-Leveling: What's Happening Now and How We Step Up

Haveyoueverfeltlikeyou'redri...

-

The Future of Auto Parts: How to Find Any Part Instantly and What Comes Next

Walkintoany`autoparts`store—a...

-

Applied Digital (APLD) Stock: Analyzing the Surge, Analyst Targets, and Its Real Valuation

AppliedDigital'sParabolicRise:...

-

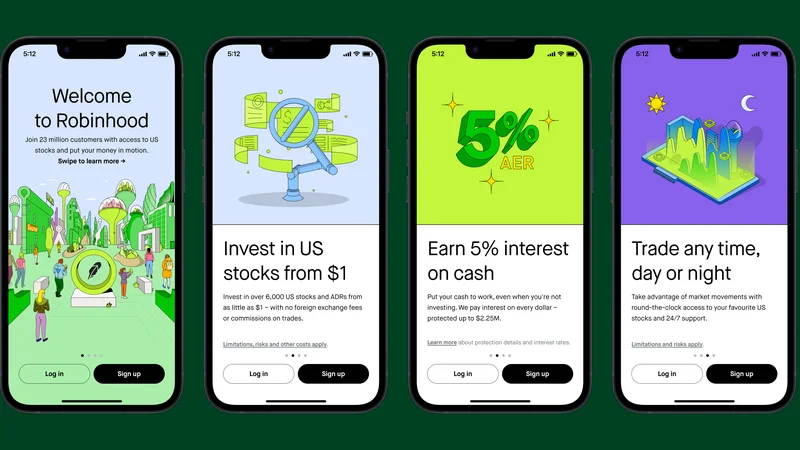

Analyzing Robinhood: What the New Gold Card Means for its 2025 Stock Price

Robinhood's$123BillionBet:IsT...

- Search

- Recently Published

-

- DeFi Token Performance & Investor Trends Post-October Crash: what they won't tell you about investors and the bleak 2025 ahead

- Render: What it *really* is, the tech-bro hype, and that token's dubious 'value'

- APLD Stock: What's *Actually* Fueling This "Big Move"?

- Avici: The Real Meaning, Those Songs, and the 'Hell' We Ignore

- Uber Ride Demand: Cost Analysis vs. Thanksgiving Deals

- Stock Market Rollercoaster: AI Fears vs. Rate Hike Panic

- Bitcoin: The Price, The Spin, & My Take

- Asia: Its Regions, Countries, & Why Your Mental Map is Wrong

- Retirement Age: A Paradigm Shift for Your Future

- Starknet: What it is, its tokenomics, and current valuation

- Tag list

-

- Blockchain (11)

- Decentralization (5)

- Smart Contracts (4)

- Cryptocurrency (26)

- DeFi (5)

- Bitcoin (31)

- Trump (5)

- Ethereum (8)

- Pudgy Penguins (6)

- NFT (5)

- Solana (5)

- cryptocurrency (6)

- bitcoin (7)

- Plasma (5)

- Zcash (12)

- Aster (10)

- nbis stock (5)

- iren stock (5)

- crypto (7)

- ZKsync (5)

- irs stimulus checks 2025 (6)

- pi (6)

- hims stock (4)

- kimberly clark (5)

- uae (5)